1 Determine requirements and provide artwork,

Determine your custom requirements, such as: gem type, 4C requirements, setting material, is it platinum or gold, is it PT950 or PT900, and other detailed information.

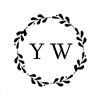

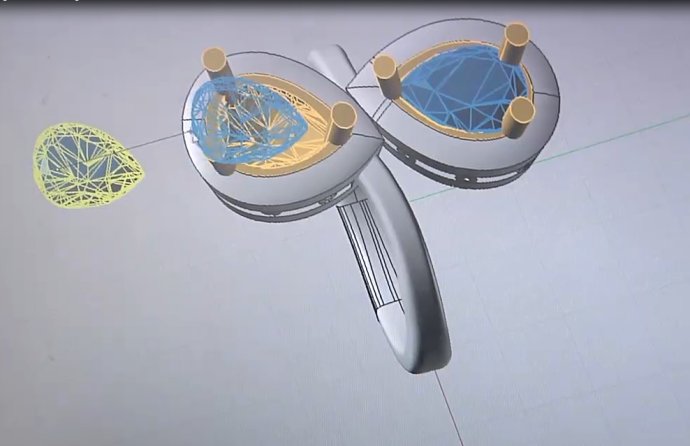

2. Confirm the design drawing, determine the final delivery date and estimated quotation,

3. The price is confirmed, the edition fee is paid, and the wax edition is made.

4. After confirming the jewelry sketch, start to make wax molds. The first wax mold is made by hand, then made into silver molds, and then pressed into wax molds with the template. After these are completed, you can use the wax mold machine to fill out the wax molds. Wax mold out. Each wax model can be reused, but if the customer requests it, he can also pay a certain fee to destroy the wax model.

5. Planting trees: After the customer wears the wax model and confirms that there is no modification, the wax model should be made into a wax model tree. The tree can have the same style of wax model (which means mass production); it can also be of different styles.

6. Casting gold: Put the wax model tree in the furnace and wrap it with gypsum. Due to the extremely high temperature in the furnace, all the wax will melt after the golden water is injected, and a gold jewelry tree will be born, and then the jewelry will be removed from the tree cut out.

7. Polishing, polishing can be done after mounting.

9.Take picture or video to finished the balance payment and dilivey